Table of Contents

- The Role of Hubs and Bearings in Vehicle Dynamics

- Impact on Comfort: Minimizing Friction and Vibrations

- Influence on Handling: Stability and Steering Precision

- The Influence of Advanced Materials and Design on Comfort and Handling

- The Role of Hub and Bearing Systems in Suspension and Load Distribution

When it comes to vehicle comfort and handling, many factors come into play, ranging from tire selection to suspension setup. However, one of the most fundamental yet often overlooked components contributing to smooth driving and precise handling is the hub and bearing system. These components play an essential role in ensuring the efficient rotation of wheels and are critical to a vehicle’s overall performance, ride quality, and safety. Understanding the interplay between hub and bearing systems and vehicle dynamics can offer insights into how these seemingly small components can have a big impact on driving comfort and control.

The Role of Hubs and Bearings in Vehicle Dynamics

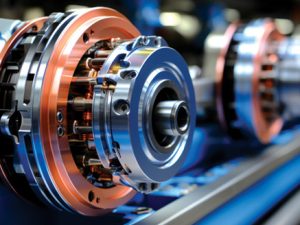

Before diving into how hubs and bearings impact comfort and handling, it’s important to understand their primary functions. The hub serves as the central part of the wheel assembly, attaching the wheel to the axle and allowing it to rotate freely. The bearing, housed within the hub, facilitates this rotation while minimizing friction between the wheel and axle. By reducing friction, bearings enable smooth movement, contributing to efficient operation, less wear, and overall vehicle stability.

In a typical car, each wheel is mounted to a hub that incorporates bearings. These systems are exposed to constant forces and stresses, which include load-bearing weight, shock absorption from the road, and rotational forces that occur when the vehicle is in motion. As such, their design and quality directly affect how a vehicle feels to drive, how it handles corners, and how it absorbs road imperfections.

Impact on Comfort: Minimizing Friction and Vibrations

Reduced Friction and Smooth Ride

One of the most significant ways that hubs and bearings influence vehicle comfort is by reducing friction between moving parts. The friction between the wheel and axle is naturally minimized by the bearing, which helps keep the vehicle running smoothly. When bearing systems function correctly, the friction between the wheel and axle is reduced, enabling a more efficient transfer of power from the engine to the wheels. This efficient power transfer results in smoother acceleration, deceleration, and cruising.

In practical terms, a well-functioning hub and bearing system prevents any additional resistance that could cause discomfort for the driver. For example, when the bearing system wears out or is improperly installed, it can cause friction or uneven wheel rotation. This can lead to vibrations that are felt throughout the cabin, making the ride uncomfortable. Modern bearings, such as ceramic and hybrid bearings, reduce friction even further, allowing for a more refined ride quality.

Vibration Reduction and Quiet Operation

Vibrations that arise from poorly performing hubs and bearings are not just uncomfortable—they can also be detrimental to the vehicle’s overall handling. Bearings that are worn or of low quality can cause uneven wheel rotation, which leads to additional vibrations and noise. The constant bouncing and unevenness can be felt in the steering wheel, pedals, and even the seat, making the ride less pleasant.

High-quality hubs and bearings play an essential role in damping out road vibrations, improving vehicle stability, and reducing noise. Bearings that are precision-engineered and properly sealed help to mitigate these vibrations by maintaining smooth wheel rotation. This, in turn, reduces the likelihood of road noise that often reaches the cabin, contributing to a quieter and more comfortable driving experience. Furthermore, modern advancements in sealed and self-lubricating bearings ensure that the system remains free of contaminants like dirt and moisture, enhancing both longevity and quiet operation.

Influence on Handling: Stability and Steering Precision

Improved Steering Precision and Responsiveness

Hubs and bearings also significantly affect vehicle handling, particularly in terms of steering precision and responsiveness. The performance of the wheel hubs and bearings directly influences how the vehicle handles during steering maneuvers, cornering, and high-speed driving.

When bearings are in top condition, they allow the wheel to rotate smoothly with minimal resistance, which ensures that the vehicle responds instantly to steering input. This translates to more accurate and responsive steering, especially during tight turns or when maneuvering in congested traffic. On the other hand, damaged or improperly functioning bearings can cause uneven wheel rotation, which can negatively impact steering feel and precision, making the vehicle feel sluggish or less responsive.

The design of the bearing system, including its size, material, and load-bearing capacity, also affects the vehicle’s ability to handle various driving conditions. For example, vehicles designed for performance or off-road use often incorporate specialized bearings that can handle the increased stresses and vibrations typical of these environments. These high-performance bearings help maintain control and stability, even under extreme conditions, ensuring that the vehicle responds exactly as expected.

Impact on Cornering Stability

Cornering is one of the most challenging aspects of vehicle handling, particularly at higher speeds. To maintain optimal stability when cornering, the bearings must ensure that the wheels rotate uniformly and at a consistent speed, despite the lateral forces exerted on them.

Advanced hub and bearing systems, such as those used in performance cars, are designed to minimize wheel slippage or imbalance when cornering. The bearings allow for precise and consistent wheel rotation, helping the vehicle track smoothly through turns and reducing the likelihood of understeering or oversteering. For instance, ball bearings and roller bearings, when used in wheel hubs, provide additional load-bearing capacity and better distribution of forces, resulting in improved cornering stability and responsiveness.

Furthermore, as vehicles become more advanced with the inclusion of active suspension systems, electronic stability controls, and torque vectoring, the bearing system must work in conjunction with these systems to ensure optimal handling performance. The integration of hubs and bearings with advanced electronic systems helps ensure that every movement of the wheel contributes to the vehicle’s dynamic handling capabilities.

The Influence of Advanced Materials and Design on Comfort and Handling

Modern Bearings and Materials

Recent innovations in bearing design and materials have further enhanced vehicle comfort and handling. The use of ceramic bearings, for example, offers significant benefits in terms of performance and comfort. These bearings, often used in high-end and performance vehicles, are lightweight, durable, and capable of handling high speeds and temperatures with minimal friction. This reduction in friction not only improves handling but also contributes to a more comfortable ride by minimizing vibrations and improving overall stability.

Additionally, hybrid bearings, which combine ceramic and steel components, provide a balanced solution for both performance and comfort. These bearings offer the low friction benefits of ceramics while maintaining the strength and load-bearing capacity of steel, resulting in superior ride quality and handling performance.

Self-Lubricating Bearings

Self-lubricating bearings have also emerged as a popular solution for improving vehicle comfort and handling. These bearings contain solid lubricants embedded in their structure, meaning they require less maintenance and are better suited for long-term, consistent performance. Self-lubricating bearings reduce the likelihood of lubrication breakdown or contamination, ensuring smooth operation even under demanding conditions. This makes them ideal for vehicles that require high performance over extended periods of time, such as racing cars or heavy-duty trucks.

The Role of Hub and Bearing Systems in Suspension and Load Distribution

Hubs and bearings do not work in isolation. They are part of a larger system that includes the suspension, drivetrain, and other structural components. The design of the hub and bearing system can significantly impact the suspension’s ability to absorb shocks from the road and distribute loads evenly across the vehicle. This interaction between the bearing system and the suspension determines how well the vehicle handles bumps, dips, and uneven road surfaces.

For example, when the bearing system is in optimal condition, the suspension can work more effectively by providing better shock absorption and load distribution. The wheel moves smoothly, and the vehicle experiences less bouncing, leading to a more comfortable and controlled ride. On the other hand, worn-out bearings can compromise the suspension’s ability to absorb shocks, leading to a rougher ride and reduced handling performance.

Conclusion: The Unsung Heroes of Comfort and Handling

While the suspension system, tires, and steering components often take the spotlight when it comes to vehicle comfort and handling, the importance of hub and bearing systems cannot be overstated. These components contribute significantly to reducing friction, minimizing vibrations, and improving steering precision—all of which enhance both ride quality and overall vehicle stability.

The integration of advanced materials and innovative bearing designs continues to improve the performance of hub and bearing systems, making vehicles smoother, more responsive, and more efficient. Whether you’re driving on the highway, cornering on a winding road, or navigating rough terrain, the quality and performance of the hub and bearing systems directly affect how comfortable and enjoyable the driving experience is.

In summary, hub and bearing systems are key players in the pursuit of a smoother, more comfortable ride, as well as superior handling. As technology continues to evolve, these components will remain essential to optimizing vehicle dynamics and ensuring the best possible driving experience for motorists.